Applicable products:

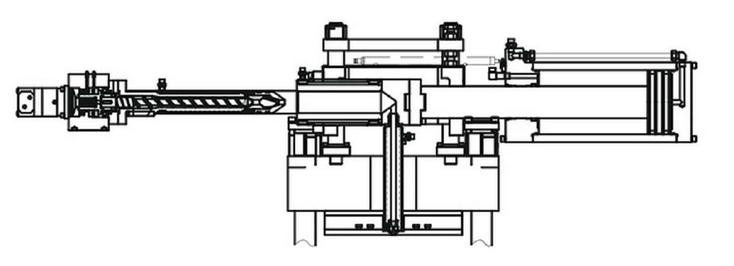

The horizontal silicone rubber injection moulding machine is mainly used in electric silicone insulation, medical silicone products, kitchen silicone wares, and other kinds of silicone parts.

Machine Characteristics:

1. The horizontal silicone injection moulding machine adopts FIFO injection structure,the injection force is stable and reliable.

2. Optimized feeding shot rod greatly reduces the rubber leakage and is convenient and fast for maintenance and rubber replacement.

3. Large capacity of feeding structure and the automatic rotary feeding barrel, efficiently feeding, suitable for fast production replacement of different colors and silicone with different property.

4. Totally enclosed safety shield and safety grating, ensuring a safe operation condition for the workers.

5. Hot plate heating zones control makes the temperature more even.

6. More automatic functions available for options.

Standard configuration for the horizontal silicone rubber injection moulding machine:

ŌŚåHigh efficient proportional pressure and proportional flow hydraulic system.

ŌŚåUpper mold core lifter.

ŌŚåLower mold in-out device.

ŌŚåtwo levels demolding device.

ŌŚåTotally enclosed safety shield and safety light curtain.

ŌŚå Independent temperature control system for plasticizing and injection.

Optional Device the horizontal silicone injection molding machine:

ŌŚåVariable pump system.

ŌŚåCold runner device.

ŌŚå3RT/4RT multi-layers demolding device.

ŌŚåMiddle mold in-out device.

ŌŚåPulling claw device.

ŌŚåMold vacuum system.

ŌŚåQuick mold changing device.

ŌŚåRemote control.

ŌŚåPrinting function.

ŌŚåEnlarged injection volume.

Technical Specification:

|

Model |

JC-RH300T |

JC-RH400T |

JC-RH500T |

|

|

Clamping force(ton) |

200 |

300 |

400 |

500 |

|

Stroke(mm) |

500 |

500 |

600 |

600 |

|

Platen size(mm) |

600x600 |

700x700 |

700x800 |

800x850 |

|

Main piston diameter(mm) |

355 |

450 |

500 |

560 |

|

Max.platen gap(mm) |

550 |

550 |

700 |

700 |

|

Min. Mold thickness(mm) |

60 |

60 |

100 |

100 |

|

Core Lifter stroke (mm) |

200 |

200 |

250 |

250 |

|

Injection unit |

||||

|

Injection volume (CC) |

2000 |

3000 |

4000 |

5000 |

|

Injection pressure (Mpa) |

188 |

182 |

178 |

178 |

|

Screw diameter(mm) |

45 |

45 |

55 |

55 |

|

Nozzle aperture(mm) |

6 |

6 |

7 |

8 |

|

Others |

||||

|

System pressure (Mpa) |

21 |

21 |

21 |

21 |

|

Horse Power(HP) |

15 |

20 |

25 |

30 |

|

Heater power (KW) |

19 |

22 |

27 |

31 |

|

Total power(KW) |

36 |

40 |

52 |

58 |

|

Weight(Kg) |

7500 |

9600 |

12000 |

15000 |

|

Dimension(LxWxH:mm) |

3400x1600x3000 |

3900x1800x3400 |

4200x2100x3900 |

4600x2300x4200 |

Notes: the form only list out the normal standard model, more special models can be customized to order.